Why the EnSURE® Touch? There is no denying that ATP systems are essential tools for food safety and quality control....

-

Hygiene Monitoring

add remove

-

Diagnostic Tests

add remove

-

Lab Equipment

add remove

- Autoclaves add remove

- Balances & Weighing Equipment add remove

- Blenders & Homogenisers

- Homogenisers

- Stomachers

- Cabinets add remove

- Centrifuges add remove

- Colony Counters & Molecular Detection

- Gas Analysis & Monitoring add remove

- Glass Washers

- Hotplates & Stirrers add remove

- Incubators add remove

- Inspection Equipment

- Meters add remove

- Microscopes add remove

- NIR Instruments

- Ovens add remove

- Photometers

- Handheld Photometers

- Spectrophotometers

- Refractometers

- Refrigeration & Freezers add remove

- Shakers, Rockers & Mixers add remove

- Thermometers add remove

- Titrators add remove

- Water Baths add remove

-

Lab Consumables

add remove

-

Brands

add remove

-

- 3M™

- A&D

- Adam Equipment

- AGC

- AJ Copes

- Analox

- Ansell

- Aqualab

- Asecos

- Atago

- Aurelia

- Aurora Scientific

- Azlon

- Azo by Vernacare

- BD

- Bellingham + Stanley

- Binder

- Biochrom

- Buchi

- Challenger

- Clifton by Nickel Electro

- Cole Parmer

- Comark

- CoolMed

- Corning

- Decon

- DeLaval

- Delvo

- Detectamet

- Dimanco

- Ebro

- Eppendorf

- Esco

- ETI

- EUTECH

- Funke Gerber

- Gem Scientific

- Genesys

- Genlab

- Geotech

- Gerber Instruments

- Gilson

- Grant Instruments

- Greiner Bio-One

- Hach

- Haier Biomedical

- Hanna Instruments

- Horiba

- Hydrosense

- Hygiena®

- IDEXX

- IK

- IKA

- Jaytec

- Jenway

- JIM Engineering

- Johnsons

- Labcold

- Liebherr

- Lovibond

- Lynd Products

- Medline Scientific

- Meter

- Mettler Toledo

- Miele

- Milwaukee Instruments

- Minebea Intec

- Monmouth Scientific

- Motic

- MSE

- Neogen®

- Ohaus

- Olympus

- Oxoid

- PDI

- Prestige Medical

- Priorclave

- Purite

- Pyrex

- r-Biopharm

- Rotronic

- S. Murray & Co

- Sartorius

- Schaller

- SciQuip

- Senses

- Seward

- SLS

- Solotech

- Solus

- Steris

- Stomacher

- Stuart

- Surfaceskins

- Sychem

- Testo

- TSC

- Uniglove

- Virkon

- VWR

- Whatman

- Wheaton

- Whirl-Pak

- WTW

- Xylem

- YSI

- Zahm and Nagel

- Zenith

-

- Sale & Offers add remove

- Knowledge Hub add remove

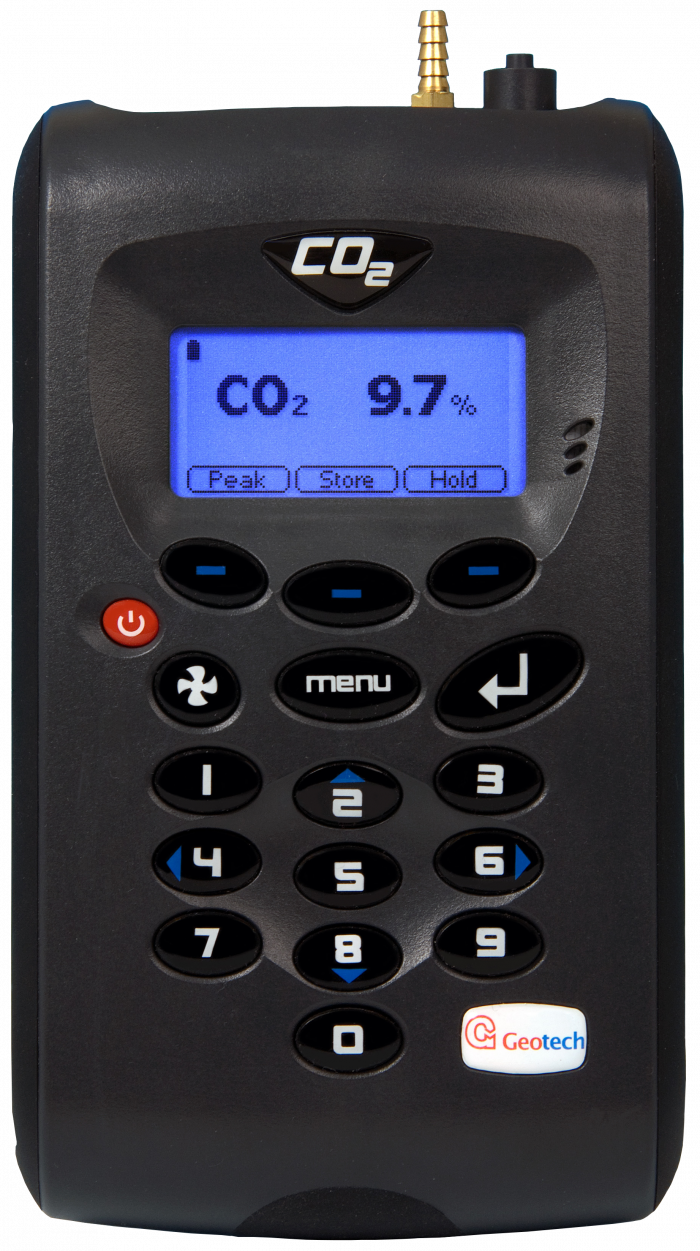

To guarantee CO2 quality assurance, Diageo sought recommendations from across the industry, and all endorsements suggested the global leader in the design and manufacture of gas analysis technology, Geotech. Confident they were using a tried and tested solution, in 2008 Diageo partnered with Geotech through its UK distributor GEM Scientific. They have since enjoyed a decade of working together to ensure the ultimate in product quality.

Over the past ten years, Geotech and GEM Scientific have worked with Diageo to refine its processes and share industry-leading product innovations. Diageo currently utilises over 60

To guarantee CO2 quality assurance, Diageo sought recommendations from across the industry, and all endorsements suggested the global leader in the design and manufacture of gas analysis technology, Geotech. Confident they were using a tried and tested solution, in 2008 Diageo partnered with Geotech through its UK distributor GEM Scientific. They have since enjoyed a decade of working together to ensure the ultimate in product quality.

Over the past ten years, Geotech and GEM Scientific have worked with Diageo to refine its processes and share industry-leading product innovations. Diageo currently utilises over 60